SSFD-5000 freeze dry machine (freeze-drying area: 5000m2) (This model is a split model of rail car and quick freezing warehouse) To build a large-scale freeze-drying production line, it is possible to consider using or customizing the largest freeze-drying equipment. This freeze dry machine has a remote terminal system that can be viewed and operated simultaneously on both PC and mobile devices. However, the processing capacity of the largest single freeze-drying equipment is only 2.5 tons or a batch of 3 tons. Therefore, if the required daily processing capacity reaches 50 tons, the freeze-drying equipment must be customized and feasibility studies for transportation and installation must be conducted in advance. If the daily processing capacity is less than 50 tons, multiple freeze-drying equipment systems will be the ideal solution for large-scale freeze-drying production lines. Each freeze-drying equipment weighs approximately 2.5 tons, with multiple or dozens of units forming the production line. Every freeze-drying equipment is of standard size, so it must be cost-effective in terms of price, transportation, installation, and other aspects. Each individual freeze-drying equipment consists of a warehouse, a quick freezing warehouse, a monorail I-beam, a trolley for material movement, a pallet for material loading, and a support system including refrigeration, external cooling, vacuum, circulation, heating, defrosting, and control. However, adding a refrigeration system to the quick freezing warehouse is a good choice for optimizing the efficiency of multiple freeze-drying production lines, and the number of quick freezing warehouses will also decrease accordingly. Therefore, this will help save pre freezing time. This device has EU CE certification.

specifications model | SSFD-2500(两台) |

Freeze dried area(m2) | 250m2 |

Tray area(m2) | 250m2 |

Loading capacity(kg) | 2500kg |

Water supplement capacity of cold well(kg) | 4500kg |

External dimensions(L* W * H mm) | Φ2200×10500+Φ2200×5500+(Host size) |

2200×7500mm (Auxiliary machine size) | |

3000×12500×3000mm (Quick freezing storehouse) | |

Plate layer temperature(℃) | 30~100℃ |

Cold well temperature(℃) | -30~-65℃ |

Vacuum degree in the chamber(pa)) | 30pa |

Heating method | Steam Heating |

Industrial control host brand | Siemens PLC |

Installed power | 420KW |

Equipment weight | Weighing before delivery |

Application display

About us

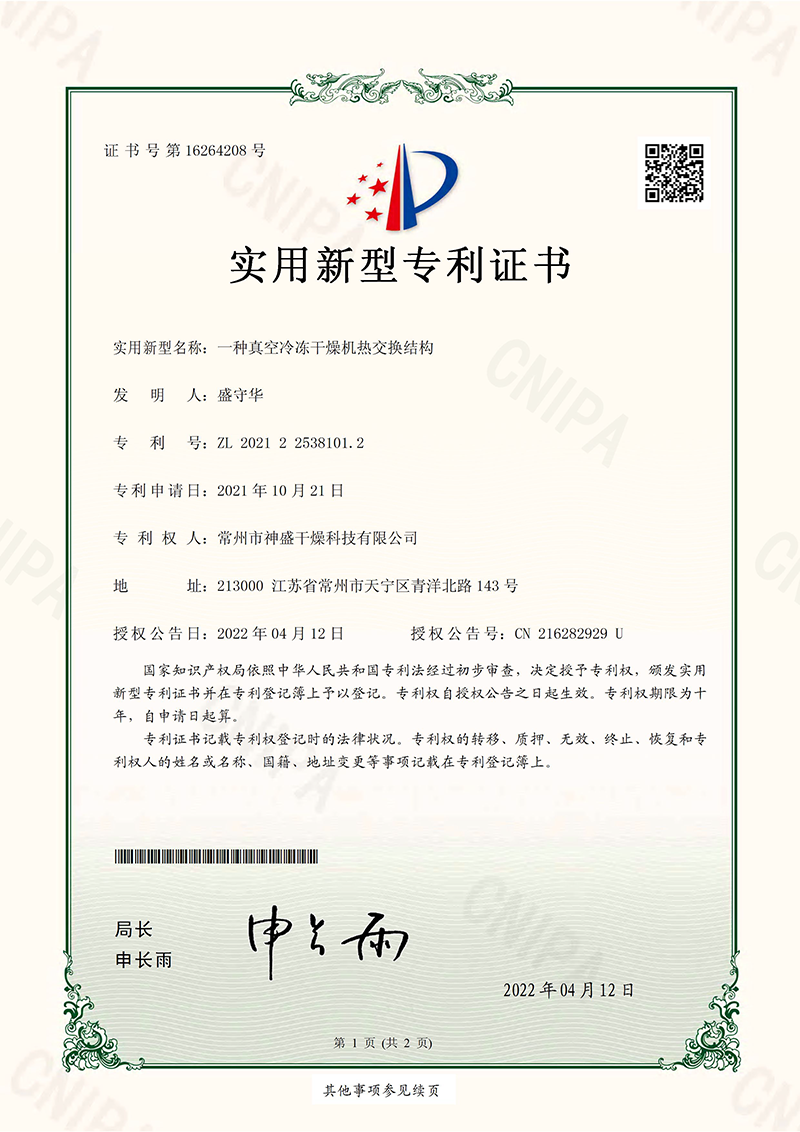

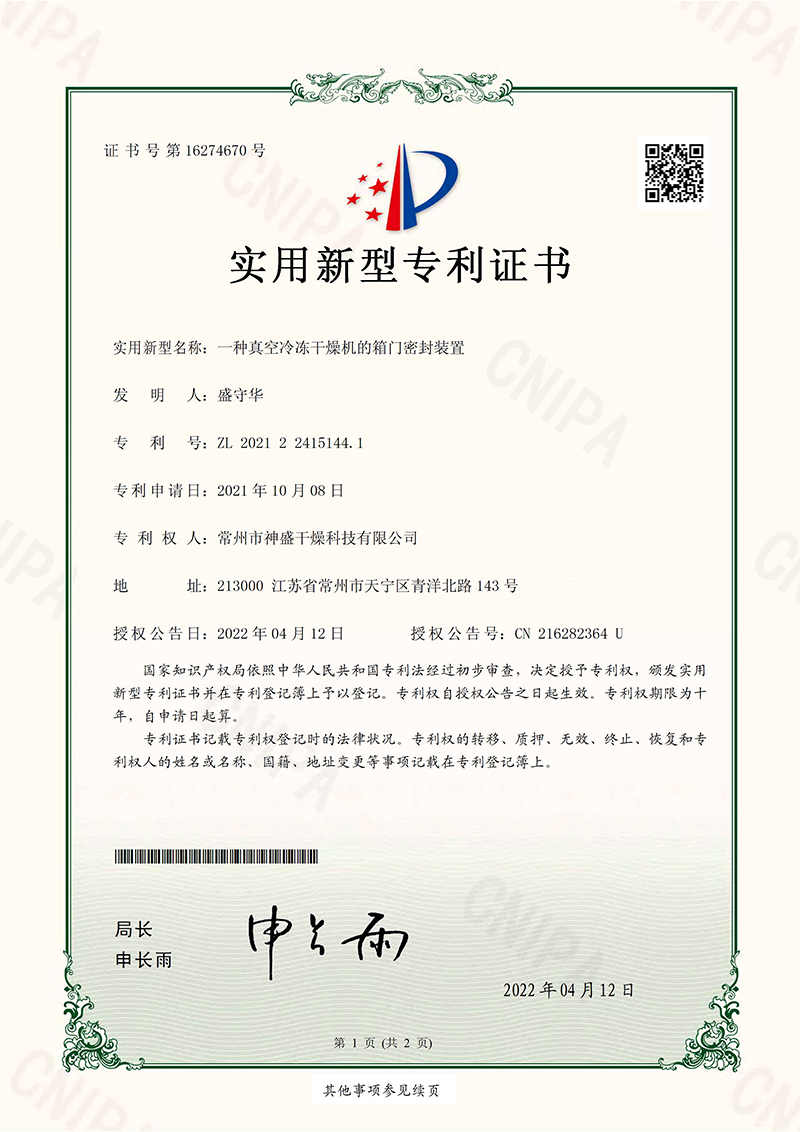

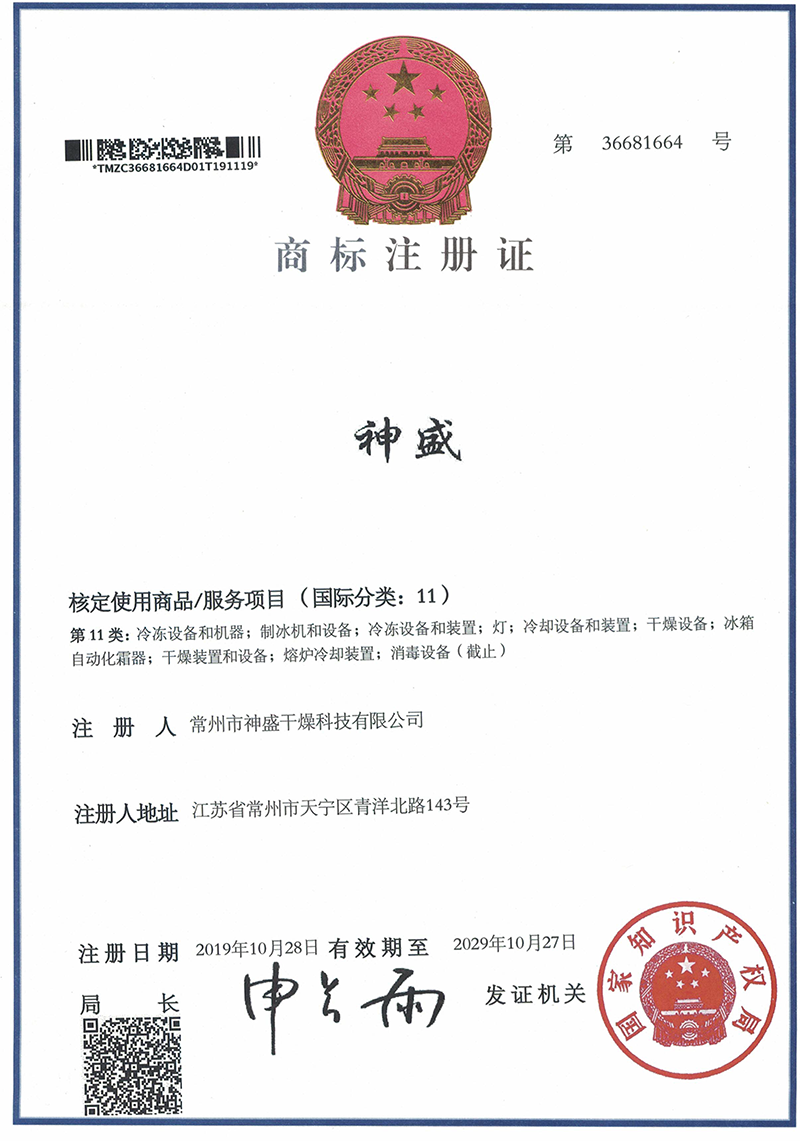

SHENSHENGThe company is located in Zhenglu Industrial Park, Tianning District, Changzhou City. It is a drying technology enterprise that integrates research and development, design, production, sales, and service. The company independently produces and sells freeze-drying machines, vacuum freeze-drying machines, pharmaceutical equipment, food equipment, and various production lines; Research and development of automation systems.

FAQ

Q:What is the working principle of freeze dryers ?

A:Freeze dryers remove moisture from wet liquids or solids by freezing them and then subjecting them to a vacuum environment. This process transforms the material into a dry powder or solid, extending its shelf life and stability.

Q:How do I choose the right freeze dryer model for my needs ?

A:Selecting a model depends on factors such as vour application, sample volume, freezing capacity. temperature control reguirements. and more. Our experts can provide customized recommendations.

Q:What are the key maintenance and care steps for freeze dryers ?

A:Maintenance involves regular cleaning, temperature control calibration, and replacing consumables like silicone gaskets to ensure the smooth operation of the freeze dryer.

Q:How can Iontimize the freeze-drving process to improve efficiency ?

A:Optimizing the process includes sample pretreatment. setting appropriate temperature and vacuur conditions. and monitoring the freeze-drving process to achieve the best results.